Why would an ECM motor be based on a DC motor instead of an AC?

Why would an ECM motor be based on a DC motor instead of an AC?

Why is a DC motor more efficient than an AC motor?

Where is the secret to DC motors to improve the shortcomings of AC motors such as inefficiency, single speed, noise, and heat generation?

A. The main reason why DC motors are more efficient than AC motors

In general, the biggest difference between traditional AC motors and DC motors is the power supply design. The traditional AC motor uses alternating current, that is, the power provided by the general socket, the structure is relatively simple, while the DC motor will firstly convert the current from alternating current to direct current via the components of the drive board, and then drive the rotation through the electromagnetic effect between the permanent magnet or coil. The AC motor controls the number of drive coils through a mechanism similar to a switch, so that only a small number of segments can be adjusted in terms of the strength of the speed. DC motors, on the other hand, are precisely controlled by "variable resistance" or PWM, which can create the effect of unsegmented or ultra-low-speed rotation.

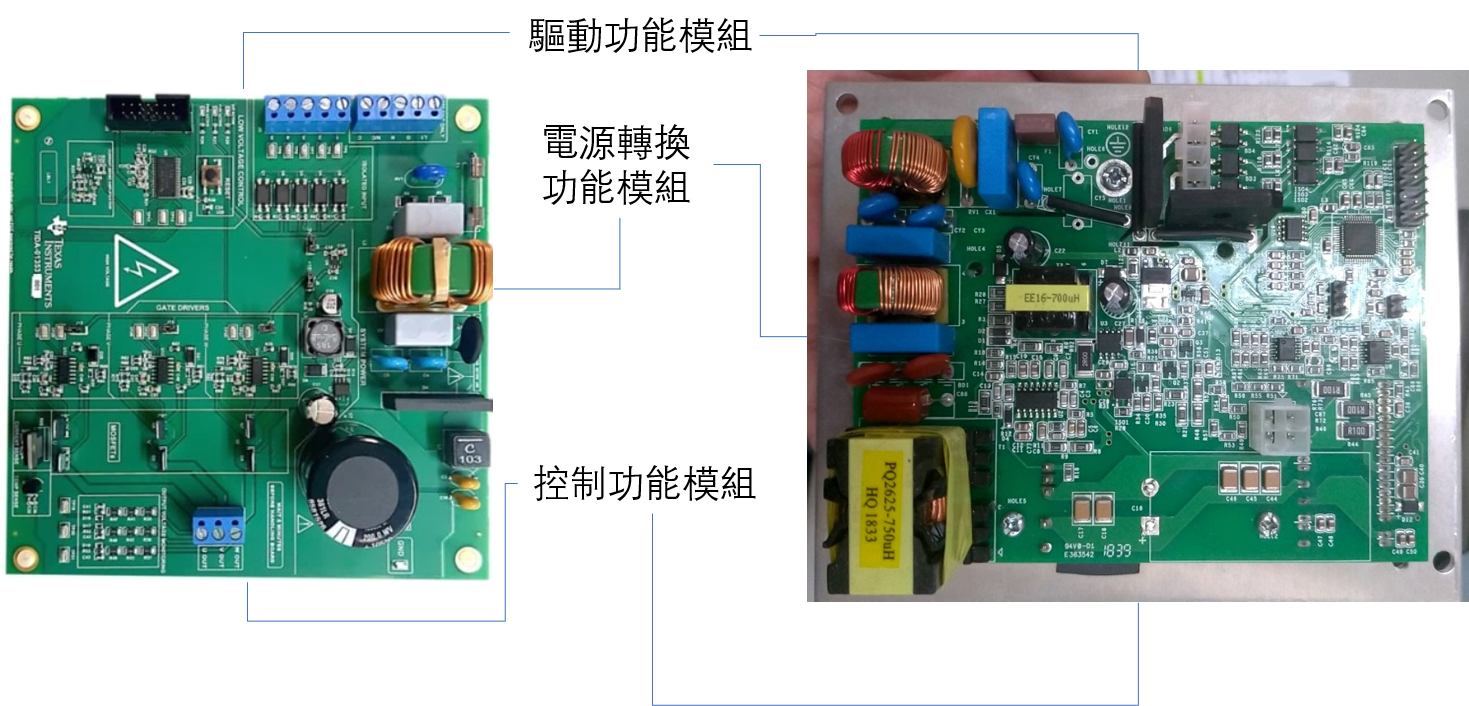

The basic structure of ECM is a DC motor, but the core of ECM lies in the design of the circuit control board, which is improved to make the motor run more efficiently. ECM motor circuit board design basic structure, generally have a drive function module, mainly responsible for driving the engine rotation; power conversion function module, mainly the input of alternating current for processing to control the DC motor; control function module, mainly can add some automatic control, inductors and other functional components, so as to more intelligent control motor.

Figure 1. ECM motor driving and controlling board design basic structure, drive function module, power conversion function module, control function module motor

B. The reason why the DC motor has lower heat than the AC motor

AC speed control motor’s conversion efficiency is only about 40%-50%, the remaining 50% -60% will be converted into heat, so AC speed control motor will be so hot because of poor conversion efficiency.

DC brushless motor’s conversion efficiency is up to 80% -85%, only the remaining 15% -20% converted into heat, so the temperature rise of DC brushless motor is only about 40-50 degrees Celsius, and AC motor due to poor conversion efficiency factors, so the temperature rise of AC speed control motor will be as high as 70-80 degrees Celsius.

C. The reason why the DC motor has low vibration compared to the AC motor

AC speed control motor - due to the AC governor internal circuit principle and motor conversion rate factors, AC speed control motor speed change rate of ±3-5%, if the need for smooth operation of the occasion, but the motor speed rate of change is large, the operation process will be fast and slow feeling, AC speed control motor is not suitable. DC brushless motor - because of the internal circuit principle of the DC brushless governor, with a speed compensation function, if the target speed and the actual speed is different, the driver will increase / decrease the current to achieve the target speed, so the BS series of load, voltage, temperature speed rate can be within 0.03% of the ±, very suitable for use in the demand for stable speed occasions, such as: loading liquid runner or LCD panel conveyor.