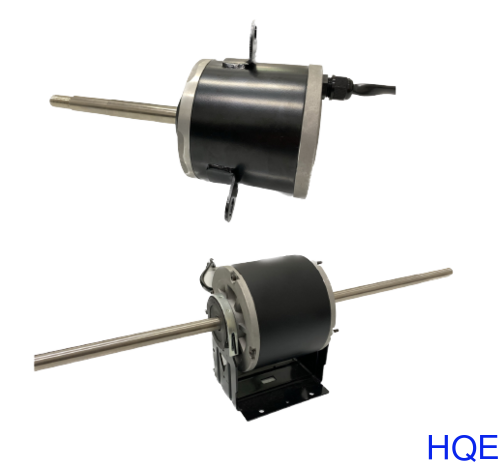

750W,1HP Motor

HQE 0.5~2HP Motor Introduction

Huaquan-Energy (HQE) has the capabilities of developing software and hardware of the motor. HQE mainly develops high-level energy-saving ECM motors, which’s full name is three-phase full-string wave heteropolar permanent magnet synchronous motor, has been widely installed in high-end hotels, hospitals, laboratories, shopping malls at the domestic and oversea. HQE not only provide customers with a good product experience, but also reduce the power consumption of products, which is welcomed by the majority of customers and manufacturers.

HQE's motors outperform other motors

The 750W motor developed by our company is an ECM electronically controlled commutation DC motor, and the basic structure is a DC brushless BLDC. It is very different from the traditional widely used AC motor structure. DC motors outperform AC motors in terms of efficiency, noise, temperature rise, interference, etc. (Figure 1).

Figure 1 Comparison of HQE ECM motor with other motors

HQE's ECM motor core technology

The reason why our ECM motor can outperform other types of motors, its core technology lies in two aspects: one is that the basic structure of our motor is BLDC, and the other is that the drive board we self-designed is stat of the art worldwide. The biggest difference between the BLDC motor structure and other types of motors is that the permanent magnet is the rotor, the winding coil is the stator, and the electronic control is used for three sets of commutation to drive the rotor rotation, and the brush is no longer needed for commutation, which eliminates the risk from brushes as consumables, high maintenance costs, heating up and other issues. In addition, the ECM motor we designed has a drive board to regulate the motor, the drive board mainly has three functional modules: First, the power conversion function module, because the power supply is generally AC power, the functional module is responsible for converting the AC power supply to a power supply that can be used to drive a DC motor; second, the drive module, the module mainly controls the drive of the motor; third, the control module, which is mainly responsible for actively regulating the state of the motor through the interactive information with the motor to ensure that the motor is in a state of efficient operation for a long time. These two features ensure that our ECM motors are energy efficient.

Figure 2: Analysis diagram of motor and drive board

HQE's ECM motor has other advantages

In addition, our motors use full-string wave electronic control technology to achieve energy efficiency, low interference, and low noise.

Therefore, in summary, the ECM motors used in HQE FCU are not only efficient but also have the following characteristics:

l Significant energy savings - high efficiency, high power factor. (IE4 rating)

l Low current harmonics, low operating temperature rise, low electromagnetic interference.

l Low leakage voltage/low leakage current.

l Flexible start-up, low noise, low vibration.

l Artificial intelligence sensor-less detection and control.

l Traditional control can be applied, and the replacement of old is doable.

l Built-in drive, complete drive/motor protection.