FCU series motors

HQE FCU motor introduction

Huaquan-Energy (HQE) has the capabilities of developing software and hardware of the motor. HQE mainly develops high-level energy-saving ECM motors, which’s full name is three-phase full-string wave heteropolar permanent magnet synchronous motor, of which the development of FCU (fan coil unit) fan motor, has been widely installed in high-end hotels, hospitals, laboratories, shopping malls at the domestic and oversea. HQE not only provide customers with a good product experience, but also reduce the power consumption of products, which is welcomed by the majority of customers and manufacturers.

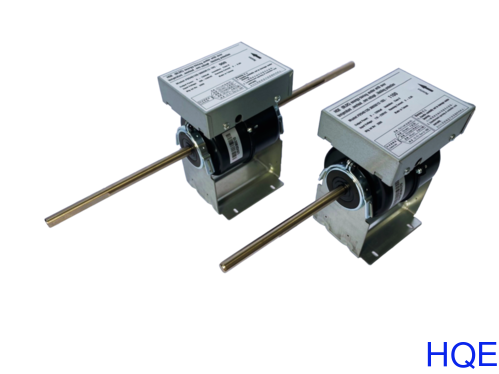

Outlook of FCU motor and its imported product fan coil unit

HQE's FCU motors outperform other motors

The FCU motor developed by our company is an ECM electronically controlled commutation DC motor, and the basic structure is a DC brushless BLDC. It is very different from the traditional widely used AC motor structure. DC motors outperform AC motors in terms of efficiency, noise, temperature rise, interference, etc. (Figure 1).

Figure 1 Comparison of HQE ECM motor with other motors

HQE's ECM motor core technology

The reason why our ECM motor can outperform other types of motors, its core technology lies in two aspects: one is that the basic structure of our motor is BLDC, and the other is that the drive board we self-designed is stat of the art worldwide. The biggest difference between the BLDC motor structure and other types of motors is that the permanent magnet is the rotor, the winding coil is the stator, and the electronic control is used for three sets of commutation to drive the rotor rotation, and the brush is no longer needed for commutation, which eliminates the risk from brushes as consumables, high maintenance costs, heating up and other issues. In addition, the ECM motor we designed has a drive board to regulate the motor, the drive board mainly has three functional modules: First, the power conversion function module, because the power supply is generally AC power, the functional module is responsible for converting the AC power supply to a power supply that can be used to drive a DC motor; second, the drive module, the module mainly controls the drive of the motor; third, the control module, which is mainly responsible for actively regulating the state of the motor through the interactive information with the motor to ensure that the motor is in a state of efficient operation for a long time. These two features ensure that our ECM motors are energy efficient.

Figure 2: Analysis diagram of motor and drive board

HQE's ECM motor has other advantages

In addition, our motors use full-string wave electronic control technology to achieve energy efficiency, low interference, and low noise. Therefore, in summary, the ECM motors used in HQE FCU are not only efficient but also have the following characteristics:

l Significant energy savings - high efficiency, high power factor. (IE4 rating)

l Low current harmonics, low operating temperature rise, low electromagnetic interference.

l Low leakage voltage/low leakage current.

l Flexible start-up, low noise, low vibration.

l Artificial intelligence sensor-less detection and control.

l Traditional control can be applied, and the replacement of old is doable.

l Built-in drive, complete drive/motor protection.

l IEC60034, CNS14400, RoHs2 Certificate

HQE's FCU motor has third-party measured data

We ourselves say that our products is energy-saving is not convincing enough, there are two convincing cases of ECM motor installation, one is a branch of the first bank, the other is a hospital in Taipei, the measurement data provided by a third party. We can clearly see that in the first bank, no matter which speed, the energy saving rate is more than 50%, especially at high speed operation, the wattage consumption has dropped from the original 1546W to 598W, and the energy saving rate has exceeded 61.3 %。 This energy saving rate is very impressive, long-term use, the saved electricity costs can not only offset the cost of the motor itself within one year, and in the next year can save hundreds of thousands of electricity bills, which does not take into account the cost of reducing maintenance costs and so on.

In addition, a hospital in Taipei also installed our FCU motor, there is a significant energy-saving effect, of which the wattage at medium speed dropped from the original 92.4W to only 23.9W, and the energy-saving effect was directly reduced to 74%. Such a considerable energy-saving rate can not only help the property owner save electricity bills, but also help the hospital apply for energy-saving medals, increasing hospital ratings, etc., so that the hospital is not only a place for saving life and wounded, but also a role model of energy conservation.

In addition, our energy-saving FCU motor has also been tested by the Taiwan Green Productivity Foundation, and the results are also very surprising. The motor used by the original owner is an internationally renowned brand motor, replaced by our 120W three-speed ECM motor, and the energy saving rate is as high as 70.6%. The specific appearance and label of the motor used are as follows:

In the Green Productivity Foundation report, we saw that they used the power meter for Hioki 3169-20, and set up instruments in real circumstance to measure, and it should be noted that they were not disassembling to measure, which there will be bias in the measurement, while measuring the instrument and motor installed on the fan in the real circumstance can truly reflect the power consumption and energy saving extent. The results were exciting, and we measured the power corresponding to the low, medium, and high speed before the installation, and compared with the improved low, medium, and high speed, and found that the efficiency increased by 71%, 64%, and 59% respectively.

|

|

Voltage V |

Current A |

Power W |

Efficiency improvement% |

||

|

Before improvement |

After improvement |

Before improvement |

After improvement |

|||

|

high speed |

217.29 |

0.6818 |

0.2975 |

147.5 |

60.1 |

59.3% |

|

Medium speed |

217.75 |

0.5335 |

0.2080 |

114.7 |

40.5 |

64.7% |

|

low speed |

217.73 |

0.4251 |

0.1456 |

90.6 |

26.6 |

70.6% |

HQE's FCU motor project performance

HQE's FCU motors have been widely installed in many places at home and abroad, including Hong Kong/Macau Five Star Hotel and Public Facilities, Sun Moon Lake Five Star Hotel, Taipei Tianmu Well-known Hospital, Beitou Well-known Hospital, Taoyuan Well-known Hospital, Kaohsiung Well-known Language Institute, Taiwan Railway, Tainan Well-known Packaging Material Manufacturing Factory. Widely acclaimed.

Analytical conclusions

1. Energy-saving part:

For commercial buildings, hospitals or restaurants with high usage hours and high utilization rates, 200 fans combined with HQE ECM can save 1865.15 yuan * 200 units = 373,030 yuan per year based on 16 hours of daily use and 365 days of operation.

2. Temperature rise part:

After 30 minutes of operation (the motor temperature reaches thermal equilibrium), AC Motor reaches a temperature that cannot be touched by the human (above 50 °C), while the HQE ECM is a human touchable temperature (below 37 °C); the high temperature rise motor will significantly reduce the cooling effect of the blower.

FCU motor catalog table

|

HQE FCU motor catalog |

|||

|

Model |

10F-100S(D)-TS |

10F-120S(D)-AS |

10F-120S(D)-VS |

|

Speed adjust |

TS dip switch model |

AS adjustable model |

VS stepless model |

|

Thermostat type |

Traditional H/M/L three speed thermostat |

0~10V stepless thermostat |

|

|

Speed range |

0~1170rpm |

0~1100rpm |

500~1100rpm |

|

Input voltage |

200~240V |

110~220V |

200~240V |

|

Frequency |

50 / 60Hz |

50 / 60Hz |

50 / 60Hz |

|

Current |

0~0.75A |

0~0.8A |

0~0.8A |

|

Isolation |

B |

B |

B |

|

Ambient Temp |

-10℃~+45℃ |

-10℃~+45℃ |

-10℃~+45℃ |

|

Waterproof |

IP42 |

IP42 |

IP42 |

|

Speed adjust operation |

Dip switch: 00、01、10、11 four levels to switch |

Panel control is used to adjust to any three speeds |

Controlled directly by users via stepless thermostat |

|

Note |

Model code rule example:10F-100D00 (10F stands for FCU product, 100 is 100W power, S/D represent single or double shaft). Product name example:F0940080-300S012-105(F094 represents diameter of stator is 94mm,0080 stands for 80W power, 300 is shaft length, S/D stands for single/double shaft, 012 stands for shaft diameter, 105 is foot stand height) |

||