The whole world is developing ECM motors, stopping at BLDC (DC brushless) is outdated!

The whole world is developing ECM motors, stopping at BLDC (DC brushless) is outdated!

What is an ECM motor?

Why is it so energy-efficient?

ECM (Electronically Commutated motor) motor, the direct translation is motors using electronic technology to control commutation (Figure 1), is a motor with a control module, the control system generally with a variety of sensors, such as pressure, temperature, angle, flow. It is used to control the information collection of the control system, to achieve the role of feedback regulation.

The ECM motor consists of a microprocessor, which is a programmable special integrated circuit processor. Such a processor, all its components miniaturized into one or more integrated circuits. An integrated circuit that accepts a coded instruction at one or more ends of it, executes the instruction, and outputs a signal that describes its state. These instructions can be entered, centralized, or stored internally. Also known as the semiconductor central processing unit (CPU), it is a major component of microcomputers. Components of a microprocessor are often mounted on a single chip or within the same component, but are sometimes distributed across different chips. In a microcomputer with a fixed instruction set, the microprocessor consists of an arithmetic logic unit and a control logic unit.

This microprocessor regulates air flow by controlling the motor. Every minute the motor rotates by accelerating or decelerating, keeping the air flow stable. This will make the air conditioner or heater run at the highest efficiency, rather than running the fan at a constant high speed, it will adjust the speed according to the conditions, so that the fan will sometimes run at a low speed to achieve energy savings. This is one of the ways ECM motors save energy.

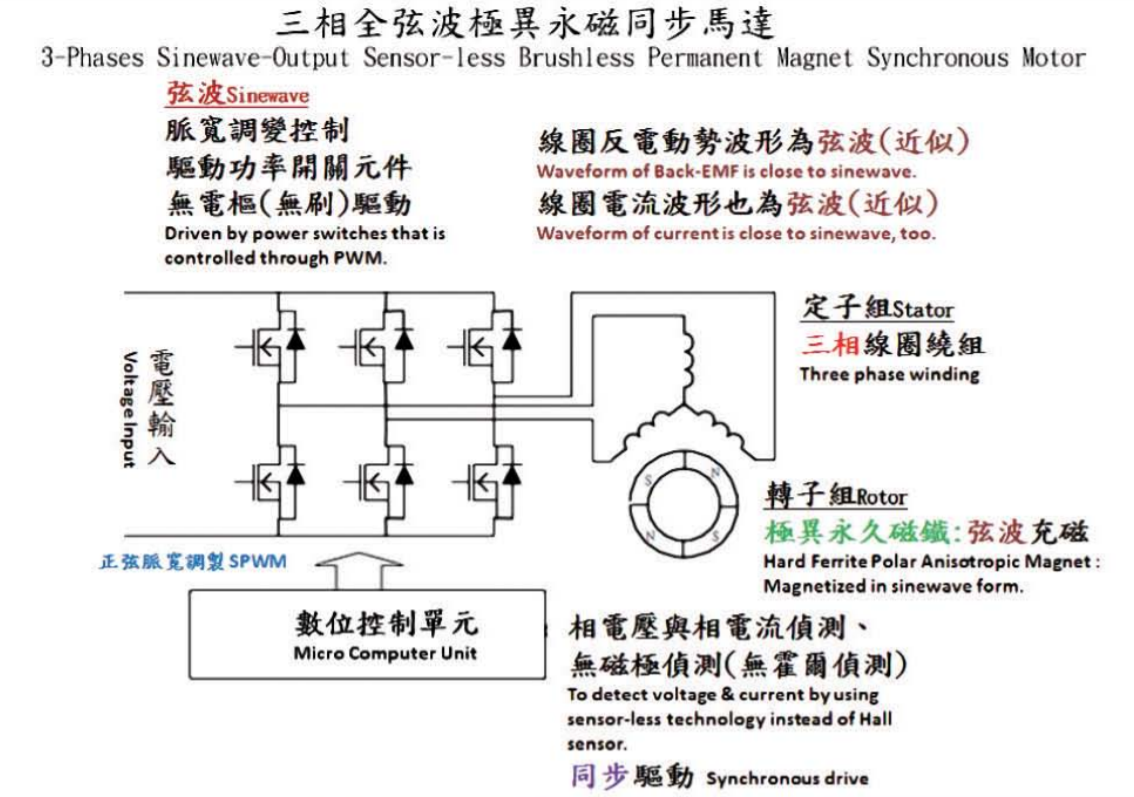

The main feature of BLDC (Brushless) motors is that there is no longer a need for brush commutation, but use electronic technology to control instead. The brush of the traditional brush motor is generally a carbon rod or carbon material, and long-term wear is easy to cause motor damage, heat is also dangerous, and maintenance costs are high. The BLDC motor in the technical breakthrough makes the DC motor once again valued and developed, it can be said that BLDC is an epoch-making motor invention and improvement, and the basic structure of the ECM motor is the BLDC motor, on this basis, it is the use of three-phase full-string wave technology, through the rational design of MCU microcontroller components, combined with the drive board and control module will be DC motor technology to a higher level.

Figure 1. ECM basic component graph, the left square for the internal picture, the right part for the single- and double- shaft ECM motor product, the left side of the internal diagram is the control module, can also be square, the middle part is a three-phase stator, the right part is the rotor and the shaft, the shaft can also be a double-shaft